On moving to live here to Wales we decided to try and make the house as inexpensive and as environmentally friendly to run as we reasonably could. Not because we are ideologically driven but because it seems to make sense and we would like the house to be as comfortable as possible.

With the government scheme to pay a feed in tariff for home generated electricity it also seemed to make sense purely from a financial point of view if we had a bit of spare cash sitting in a low interest account. We originally looked at this in November 2010 and the installation costs for a 4kw domestic installation was then around £15,500. Since then the price of PV panels has dropped considerably. Unfortunately the government subsequently took a rather hasty decision to suddenly cut the tariff paid to householders. So we had ‘missed the boat’. However, this knee jerk reaction hit the industry hard and panel prices subsequently continued to fall in price.

So when we reviewed things at the end of January 2012 the installation costs had nearly halved; meaning that the return on investment would almost be the same. Furthermore the government’s decision is subject to ongoing legal challenge that could still possibly reverse the tariff decision. With this in mind we decided to go ahead with the installation on the south facing garage roof. There is a calculator for working out income and savings here.

Unfortunately the industry has become a bit of a ‘get rich quick’ scheme with plenty of ‘dubious’ solar panel installation companies springing up. At times it seems like the ‘Wild West’ out there! In some cases these firms are fitting installations in a pretty unsatisfactory manner; simply by drilling through slates or tiles and fitting rubber sealing grommets. Sometimes these are not even fixed into structural timbers but screwed into the battens. Even if they are watertight when fitted I can’t see how the wind loading will not put a flexing load on the slates and tiles causing some to break over time; nor can I see how the grommets will not perish over a period of time. I certainly wouldn’t want this type of installation on our garage roof let alone our house. How many of these ‘here today – make a quick buck’ operators will be around in 5 years or ten years time when these failures start to appear?

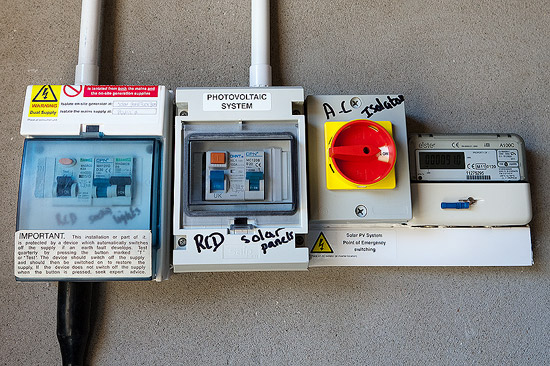

So having got a few quotes we decided to use a very local contractor Jones Electrical (who have been working in the area for over 50 years) reasoning that they were not likely to disappear next week and their reputation would be important to them. So last week their roofing subcontractor arrived and started on the roof whilst the electricians installed the wiring and inverter (which converts the D/C current from the panels into A/C for the mains).

The roofer proved to be excellent taking great care to properly fix the roof hooks to the structural timbers and to flash them all correctly with lead. The brittle Spanish slates meant he couldn’t work as fast as he had hoped but there was no way that he was compromising on the job. So full marks to the roofer and his son for their conscientious approach to the job. Jim Jones who started the electrical business 54 years ago personally turned up to check on progress and ensure that all was going smoothly. It is really refreshing to find small local businesses going the extra mile rather than just jumping on the bandwagon.

So today it was finished and the electricians came to correct an earthing problem on our existing system and to turn on the system and we are now generating our own electricity (or rather will be in when the sun shines as it was too dull by the time it was all finished). I’ll try and remember to update the blog in a years time when we know how much we are actually producing. All I have to do now is work through the paperwork to sell our electricity to our electricity supplier!

Dear John, I was very interested to read your comments about the quality of the workmanship on your solar panel installation. In particular I am interested in the way in which the panel frame anchors are attached to the roof structure. I wonder if you have any photos more close up of the installation of the anchors. It looks as if the roofer used a slate ripper as they are called to reach in under the slate to cut its retaining nail. Then the anchor is screwed to the top edge of an exposed rafter (not to a batton as that would not necessarily be strong enough) and then the removed slate cut to reduce its width to cover in down one side of the now fixed anchor. Then a piece of flat lead is inserted to go under the slates left and right and along the top, by a good margin? How is the lead fixed in place? Or maybe the lead is fixed with copper nails before the removed slate (or slates?) are replaced?

Also how have they routed the electric cable from each panel to go into the roof? Under the slates, therefore being a bit pinced by the weight of the slates, before going through a hole in the underlying felt?

Sorry to be a pest but as you say, there are too many installers out there useing methods late long term may give rise to problems with leaks etc.

We already have PV panels installed during Febuary but this is on a concrete tile roof which is easier to deal with. However, now we want to install solar thermal panels on a slate roof which will raise the same issues and in addition the job of providing a reliable and leak proof way to seal the entry of the two flow and return pipes. I agree that rubber grommets are unlikely to survive the sun, rain, hot and cold of 20 years plus.

If you have time to reply maybe with some closeup photos if only of the actual anchors used, I’d be very grateful.

Sincerely, Simon Wheeler.